Model Engineers' Workshop is the ideal workshop companion for all hobby engineers. Model Engineers' Workshop shines a spotlight on the tools and techniques used by model makers, light engineers, restorers and customisers and those who like making and modding their own tools. You'll find readers' tips, reviews of workshop equipment as well as articles on restoring old tools and making your own as well as the latest new technologies, techniques and materials. Model Engineers' Workshop magazine publishes 12 great issues a year.

On the Editor’s Bench

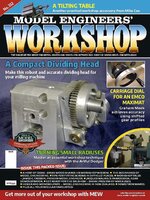

Model Engineers' Workshop

Modifying my Mini Lathe • Geoff Andrews recounts his approach to customising a mini-lathe – probably the most numerous lathes ever made.

On the Wire • NEWS from the World of Hobby Engineering

Cutting Fluid Drip Feed • Laurence Pepper explains how to make an effective device for applying small amounts of neat cutting fluid to lathework.

A Proper Handle • Derek Speddings didn’t just want a ‘proper handle’ for his Boxford AUD lathe, he wanted to achieve similar control to having a mechanical clutch.

Workshop Power • A beginner’s guide to powering your workshop from Stub Mandrel

Bob’s Better Bevels Part 2: Cutter Selection • Bob Reeve further explains his approach to making bevel gears.

BEGINNERS WORKSHOP

SPRINGS • Geometer describes the various types of springs encountered in the workshop

Digital Caliper Battery Cover

Building A Free Pendulum Clock Part 2. • Tony Jeffree experiments with sensors and modules to make an efficient pendulum.

The John Stevenson Trophy 2022 • Many readers and forum members will remember John Stevenson, a contributor to MEW but best known for his larger-than life presence on the Model Engineer forum.

Machining Internal Turning TC Tip Holders • Concluding a series of articles on making tip holders for tungsten carbide tips, Jacques Maurel explains his machining method for holders to suit internal turning tasks.

Scribe a line • YOUR CHANCE TO TALK TO US!

A New Makerspace • Editor, Neil Wyatt, visits a new facility in Penarth, South Wales, that aims to engage new people in practical creative activities.

In our Next Issue

An Improved Tailstock for a Myford Lathe - Part 3 • We are pleased to feature this improved tailstock for a Myford lathe, designed and built by Murray Lane. Using castings from his own patterns, this article echoes some of the ambitious projects of the past.

An Epicyclic Saddle Hand Wheel for a Peatol Lathe • Bernard Towers gears down his saddle to give more accurate feed control.

Jun 01 2025

Jun 01 2025

May 01 2025

May 01 2025

Apr 01 2025

Apr 01 2025

Mar 01 2025

Mar 01 2025

Feb 01 2025

Feb 01 2025

Jan 01 2025

Jan 01 2025

Dec 01 2024

Dec 01 2024

Nov 01 2024

Nov 01 2024

Oct 01 2024

Oct 01 2024

Sep 01 2024

Sep 01 2024

Aug 01 2024

Aug 01 2024

Jul 01 2024

Jul 01 2024

Jun 01 2024

Jun 01 2024

May 01 2024

May 01 2024

Apr 01 2024

Apr 01 2024

Mar 01 2024

Mar 01 2024

Feb 01 2024

Feb 01 2024

Jan 01 2024

Jan 01 2024

Dec 01 2023

Dec 01 2023

Nov 01 2023

Nov 01 2023

Oct 01 2023

Oct 01 2023

Sep 01 2023

Sep 01 2023

Aug 01 2023

Aug 01 2023

Jul 01 2023

Jul 01 2023